Temperature Mapping

Ware House Temperature & Rh Monitoring

Autoclaves, sterilizer temperature mapping

Dry Heat sterilizer, Ovens temp mapping

Incubator, cold room temperature mapping

GMP Consulting

Validation Services

GMP Compliance Audits

Risk Assesment

Supplier & Contractor Audits

Training

Cascade Impactors

Calibration

Offering a comprehensive

calibration service that can be tailored to your

requirement.

Read More..

Cascade Impactors Mensuration

Introduction To Mensuration

The Cascade Impactors performance depends on the jet dimensions, the spatial arrangement of the jet , its collection surface and the rate of airflow passing through it. These factors may affect the performance of the Impactors hence proper measurement is necessary as per the compliance with USP and EP.

The process of measuring the nozzle diameters and other critical dimensions of Cascade Impactors is called as Mensuration.

Both European and US Pharmacopoeia recommends stage mensuration of Impactors prior to use and periodically thereafter.

Mensuration at QA Tech:

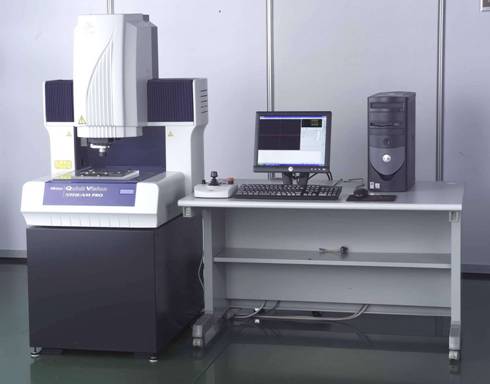

QA Tech has been providing Stage Mensuration services for Cascade Impactors since 2005 in India .The Quick Vision Measuring instrument is highly accurate and capable of Mensurating many stages automatically. The methods for Mensuration have been developed by a group of experienced people from pharma industry.

QA Tech continuously updates its methods for Mensuration as per the requirements of pharma industry & hence has become a UNIQUE SERVICE PROVIDER FOR MENSURATION in India.

The measurement of jets dimension of Impactors is done with Quick Vision Measuring System (QVX – 202 PT) of Mitutoyo .

Master Instruments List Mensuration

| Sr. No. | Instrument Name | Make | Model No. | Range | Accuracy | |

| 1 | MITUTOYO VISION MEASURING MACHINE | MITUTOYO | QVX-202PT | 200 mm x 200 mm x 200 mm | 1.5+3L/1000 µm | |

| 1.5+3L/1000 µm | ||||||

| 3.0+4L/1000 µm | ||||||